Search Knowledge Base by Keyword

Getting Started

This article will first cover the different installation statuses within Verity. Following this section is an in-depth explanation of the different Verity translations and metrics. Installation Status refers to whether a piece of geometry is installed and how much scan data covers the item. Translations and metrics refers to the mathematical differences between the as-designed and as-built geometry.

Coverage Percentage

During the analysis, Verity calculates how much scan data covers the surface of each item. Verity reports this percentage in the % Coverage column of the table. Like all columns in the Verity tables, you can sort by this information and use it to help focus your review time. While it isn’t a guaranteed metric in all cases, items with lower coverage are more likely to have errors in the fit and classification than items with higher coverage values. This column helps to identify which items are most likely to be erroneously classified or fit by our algorithm so you can more easily find them and make the necessary corrections. This is not intended to replace the process of reviewing each item and determine the results.

Installation Statuses and Conformance to Tolerance

Assuming all primary analysis steps were run, here are the installation status and conformance to tolerance values you see in the Verity table for each item and what they mean:

- Installed – Algorithm found a signature matching the geometry in the scan data.

- Uncertain – Point data was inconclusive or contradictory for this item.

- Occluded – Captured points obscured the geometry location, so we can’t tell what it is.

- Not Found – Points would have been captured if the geometry was there, so it is missing.

- Not Enough Data – There are insufficient points to analyze this item.

- No Data – There were no points in the space around the item.

- N/A – No as-built location was found, so not applicable.

For any items found to be Installed, Verity will compare the total translation against the tolerance to determine how each item conforms to that user defined tolerance. Conformance to Tolerance values can be:

- Pass – Item was installed within the specified tolerance (less than or equal to)

- Out Of Tolerance – Item was installed outside the specified tolerance (greater than)

- N/A – Not applicable because the item wasn’t found to be installed

Translation and Rotation Metrics

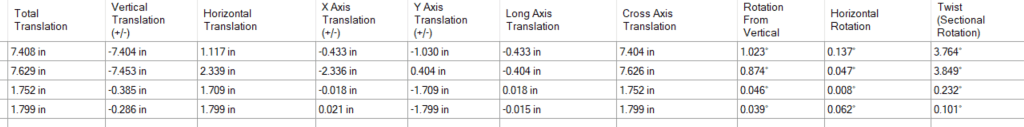

In addition to the statuses above, we also report out ten different measurements comparing the As-Built geometry back to the As-Designed geometry.

Translation Metrics

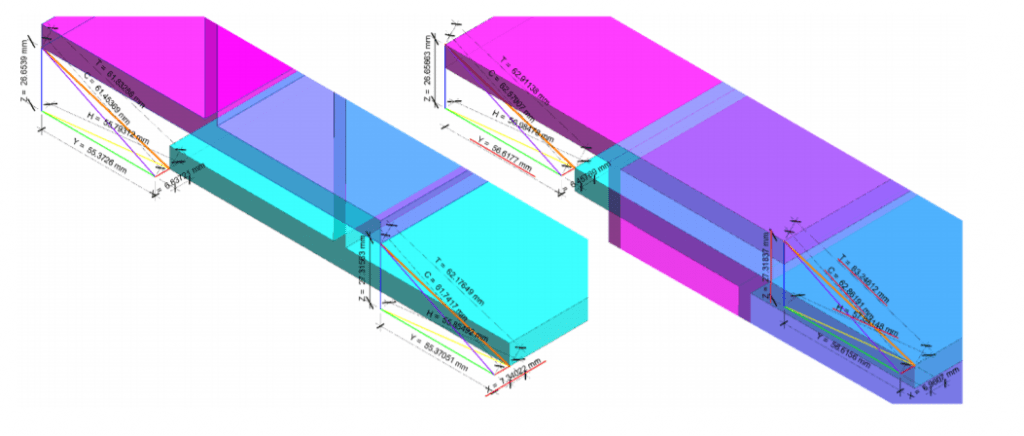

Translations are computed by taking every vertex on the As-Designed geometry and measuring the distance to the same vertex on the As-Built geometry. Those measurements are broken into vector components to isolate movements along individual planes or axes. The table reports the largest value for each element. (The diagram below illustrates this). All the measurements are taken, but only those underlined in red are published in the table. Most are taken from the top right corner of the beam, but the largest X translation occurs on the bottom right corner, and the largest Y translation occurs on the top left corner:

- Cross Axis Translation – Component vector on the plane perpendicular to the item’s long axis.

- Long Axis Translation – Component vector along the item’s long axis.

- Y-Axis Translation – Component vector parallel to the project Y-axis.

- X-Axis Translation – Component vector parallel to the project X-axis.

- Horizontal Translation – Component vector in the project XY plane.

- Vertical Translation – Component vector parallel to the project Z-axis.

- Total Translation – The linear distance between both points (used for conformance to tolerance).

The measurements made in the object’s coordinate system are not given a sign (+ or -) as that is highly subjective. Verity will assign measurements that are in the project’s coordinate system a sign when possible.

Rotation Metrics

Rotations are more complex to calculate, as different methods will yield different answers. Verity uses two different methodologies for calculating rotations based on whether the object is “typical” (anything but almost vertical) or like a column (vertical or nearly vertical). Almost vertical is when either the as-built or the as-designed is within 5 degrees of vertical (positive Z).

A) In most cases, Verity calculates the rotation from vertical and horizontal as the difference in inclination and azimuth (respectively) between the as-designed geometry and the as-built geometry. Rotations are determined by first rotating the geometry to change the inclination, then changing azimuth, with twist calculated as whatever additional rotation is needed around the long axis of the geometry to align to the as-built position.

B) In the case that the item is almost vertical, Verity calculates the rotation from vertical as the total angular difference between the as-designed and as-built geometry, with twist calculated as whatever additional rotation is needed around the long axis of the geometry to align to the as-built. In this case, the horizontal rotation will be calculated as 0 (zero).

This solution yields the most consistent results for building components in most cases. If Verity has incorrectly identified the long axis, then these calculations will not be relevant. This may happen in the case of beams or pipes with lengths shorter than their depth, for instance.