Search Knowledge Base by Keyword

Getting Started

This article will cover why the Verity algorithm might guess incorrectly, or why you might need to make manual adjustments and overrides. ClearEdge3D has developed a way to “teach” a computer to see information in point cloud data like a human can. But computers aren’t human, and this isn’t a process that can achieve perfection. At least not yet. So, the Verity algorithms are designed with certain assumptions in mind that allow them to make decisions in the face of uncertainty and process in a reasonable amount of time on your computer.

Verity Algorithm Assumptions

There are three main assumptions Verity makes:

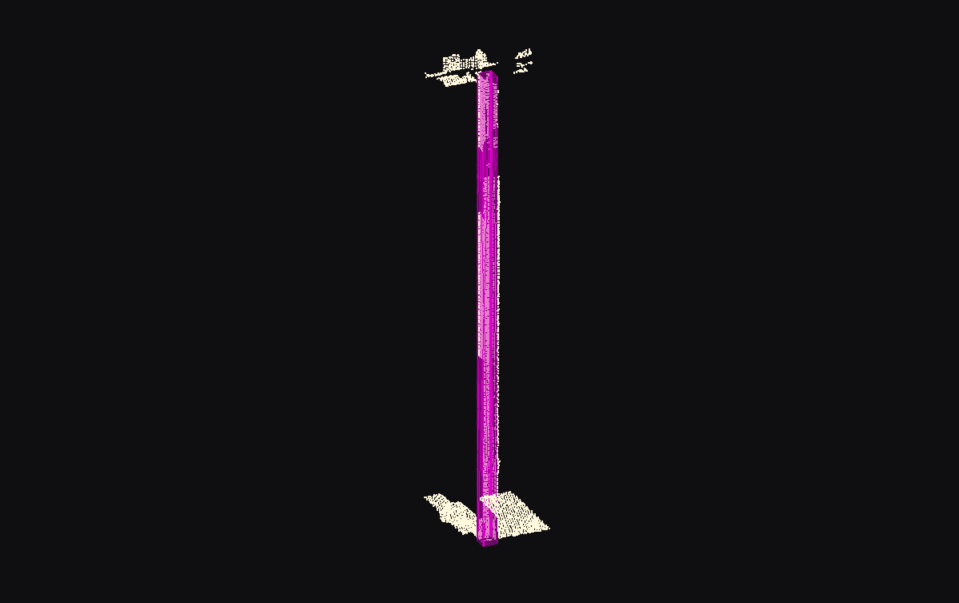

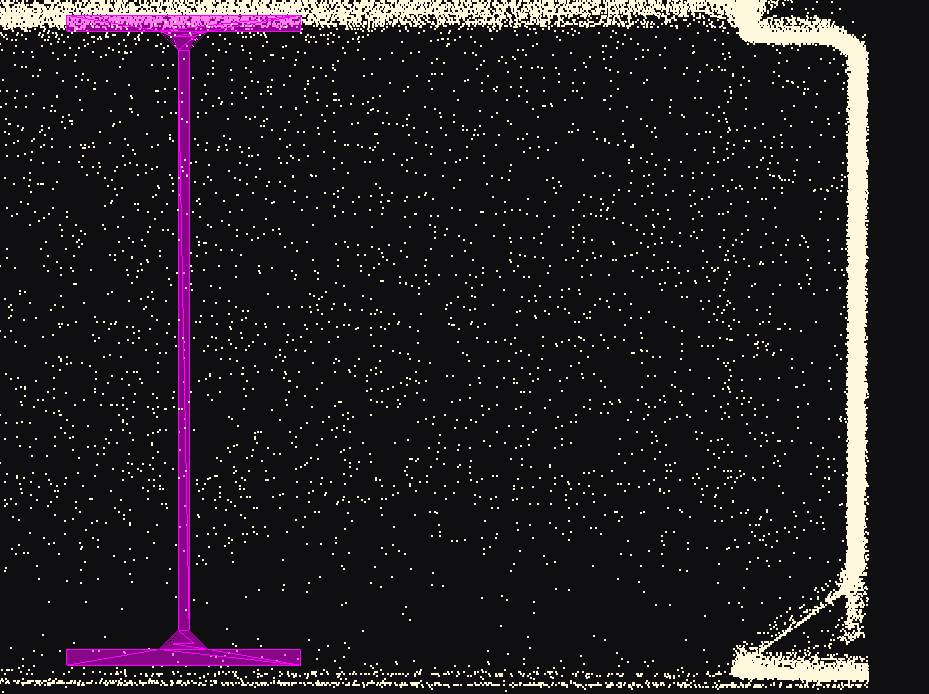

1) That the scan data is high enough quality, has sufficient coverage, and enough density to accurately determine the status and fit of the element to the point cloud. This means that if the scan data is too noisy or too sparse, Verity won’t be able to determine a result. If noise causes so much uncertainty that the algorithm won’t find a good match, it will either flag the element as Not Found or Uncertain. If the data is too sparse, the element will be flagged as Not Enough Data. For the algorithms to work optimally you want the range noise to be less than half the size of the elements you are testing, AND you need good coverage on more than one face of the geometry.

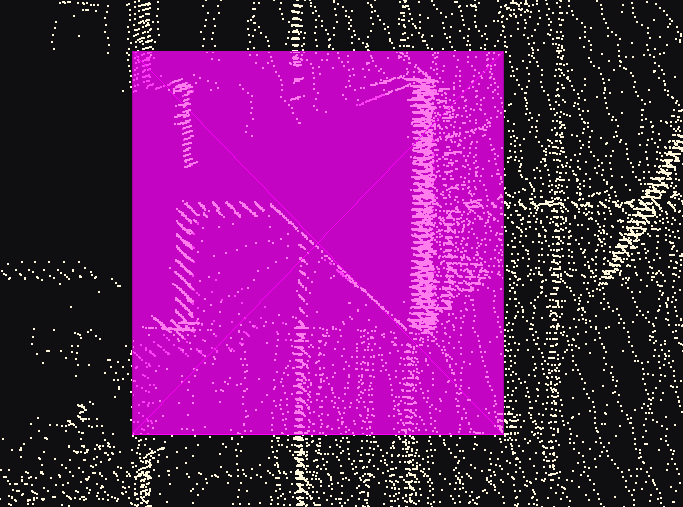

2) That the modeled geometry is very similar in shape and size to the real-world object as it was scanned. If you scanned a square penetration block out and want Verity to match it to a pipe penetrating a slab in the model, you will be disappointed in both the installation status and fit. If someone modeled the ductwork without insulation wrap and the wrap was already installed, Verity probably will guess the installation status right, but the fit will not be correct. In these cases, you can get the model corrected to match reality, OR you can manually adjust the status and fit in Verity.

3) That the installed work is reasonably close to where it should be. If the installer put the pipe in several feet/meters away from where they were supposed to, Verity will not find it. The algorithm searches within a limited area (approximately 2 feet or 600mm) of the as-designed location for a match in the point cloud. If there isn’t a good match, then Verity is going to flag that item as Not Found. If there is a poor match, Verity may flag it as Uncertain.

Grouped Geometry Fit Challenges

Groups of similarly sized elements can also be challenging for the Verity algorithms as they will find multiple suitable matches. In this case, Verity will rely on the assumption that someone installed the work as close to the right place as they could. If three 6″ pipes are all installed on a pipe rack, and the model shows three pipes, each pipe is going to be individually fit to the matching points based on proximity. If the rack is installed so that pipe A was installed closest to where pipe A was supposed to be, all is well. If pipe A was installed closer to where pipe B was supposed to be, the algorithm would match pipe A and pipe B to pipe A’s scan data, pipe C to pipe B’s scan data, and nothing to pipe C’s scan data.