In the construction industry, a quiet revolution has been gaining momentum. Virtual Design and Construction (VDC) stands at the cusp of unprecedented transformation, where technological leaps and evolving industry demands are fundamentally reshaping how we approach construction projects from concept to completion. With first-hand insights from Christian Waldo, VDC manager at Hensel Phelps, this article dives into the groundbreaking innovations reshaping VDC and shows how they’re redefining the way projects are designed, coordinated, and delivered.

Looking ahead to 2026, we’re witnessing the emergence of innovations that promise to redefine project execution, team collaboration, and outcome prediction within the VDC and BIM frameworks. These innovations mark a significant departure from incremental improvements and will transform how we deliver construction projects.

AI and Automation Reshaping VDC Workflows

Artificial intelligence has transformed the tedious process of code compliance review into an automated powerhouse. These systems can now analyze complex design models in hours rather than weeks, flagging potential issues that might have taken teams of reviewers to discover.

What’s particularly impressive is how machine learning algorithms are revolutionizing construction sequencing. When processing thousands of possible scenarios simultaneously, these systems can identify optimal project timelines that human planners might never have considered. The result? Shorter project durations and more efficient resource allocation.

The same data-driven intelligence is sharpening cost estimation. Automated quantity takeoffs with built-in error detection now catch discrepancies early, preventing small mistakes from snowballing into major budget overruns and giving stakeholders new confidence in project financials.

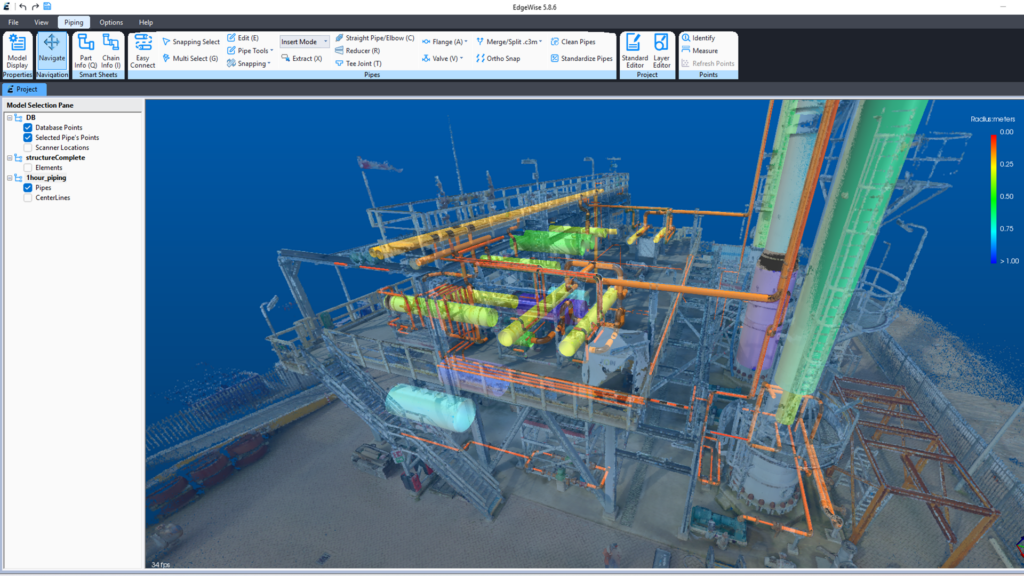

Software leveraging automation, such as EdgeWise, automated scan-to-BIM software, are improving the speed and accuracy of VDC workflows.

These advancements are also reflected in construction automation software, which is transforming how projects are planned, executed, and monitored; boosting efficiency, reducing errors, and streamlining workflows. Key tools include:

- Project Management Platforms for scheduling and collaboration

- BIM for integrated 3D modeling, including automated solutions like EdgeWise

- Automated Design & Reality Capture for rapid design and site documentation

- Verification Software, like Verity, to catch discrepancies early

- Cloud & Mobile Solutions for real-time access

- Data Analytics & AI for predictive decision-making

Together, these tools demonstrate how automation and AI aren’t just abstract trends; they’re delivering real efficiency gains and quality improvements on today’s projects.

Robotics and Automation: The Next Frontier in VDC

The HP SitePrint is changing the game in construction layout technology.

“When considering advances in construction technology, layout robots for BIM-to-field automation have achieved remarkable capabilities. These machines now pull data directly from coordinated and geo-located BIM models, executing tasks with precision that challenges traditional workforce planning assumptions. The increasing speed, capability, and efficiency of these robots are forcing the industry to rethink its approach to workforce analysis.

The verification of robotic construction work represents another leap forward. From bricklaying to excavation, from layout to assembly, robots now perform an expanding range of construction tasks. More importantly, their work is automatically verified against coordinated BIM models, ensuring perfect alignment between automated execution and design intent. This isn’t science fiction–it’s happening on job sites today, and it’s only accelerating.” Christian Waldo

Immersive Visualization: Transforming Project Understanding

Mixed reality has transcended its initial “wow factor” to become an indispensable communication tool in construction. These technologies now serve as a universal translator, helping stakeholders from various backgrounds understand complex technical plans with unprecedented clarity.

The latest rendering technologies have eliminated the traditional lag between design changes and visual feedback. Project teams can now see photorealistic representations of modifications instantly, making design reviews more dynamic and decisions more informed. This immediate visual feedback has transformed the iterative design process.

On construction sites, the revolution in mobile visualization has put powerful modeling capabilities into everyone’s hands. Site personnel no longer need specialized equipment to interact with complex 3D models–their everyday devices have become windows into the virtual construction environment. In fact, the technology provides both availability and accessibility to everyone who needs it.

“Immersive visualization (AR/VR and 4D BIM) transforms complex construction logistics into intuitive, interactive experiences, enabling the general public to easily understand phasing, sequencing, and impacts without requiring technical drawings.” Christian Waldo.

Digital Twins and IoT Creating Living Models

The marriage of IoT sensors with digital modeling has birthed a new generation of digital twins. These aren’t static representations; they’re living, breathing virtual entities that mirror their physical counterparts in real-time. Every temperature change, structural movement, and operational parameter is captured and reflected instantly.

Building owners have begun to recognize the value of digital twins throughout the entire building lifecycle, extending their utility beyond construction phases. The ability to monitor, predict, and optimize building performance long after construction completion has become a compelling selling point for technology adoption.

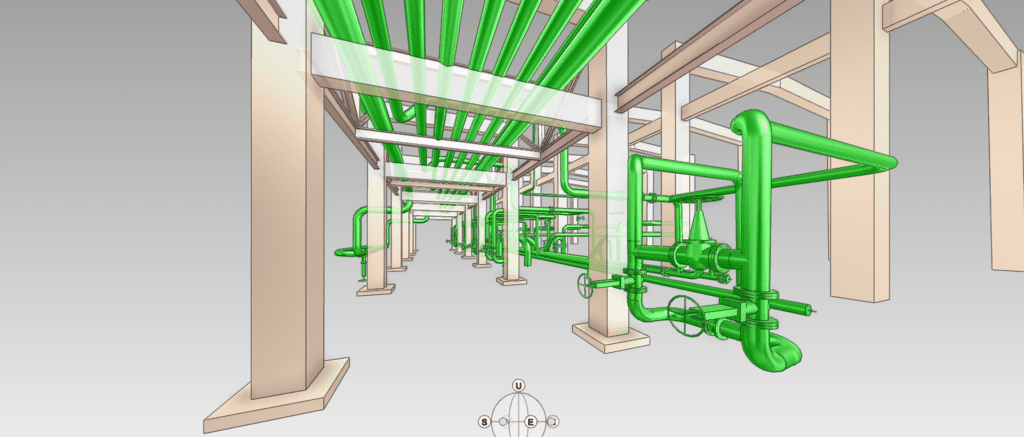

Pipes modeled in EdgeWise and imported into AVEVA E3D Design

See a digital twin come together in under an hour.

According to MarketsandMarkets, the digital twin market is projected to grow from $16.75 billion in 2024 to a whopping $110.1 billion by 2029, driven largely by real estate, manufacturing, and infrastructure sectors.

For industries like energy, oil & gas, and heavy infrastructure, AVEVA E3D Design has become a central hub for managing digital twins, combining design-grade models with continuous updates from field data. Integrations like ClearEdge3D’s EdgeWise–E3D connection further streamline this process by turning laser scans into intelligent components automatically, helping teams keep models accurate without the time and cost of manual redraws.

Point cloud data has emerged as the key validation layer for these digital twins. Regular laser scanning ensures that virtual models maintain their accuracy over time, creating a feedback loop that keeps digital representations perfectly aligned with physical reality. Companies using digital twins in construction and operations have seen 10–20% reductions in operating costs due to improved predictive maintenance and performance monitoring. Without this validation, digital twins would be just sophisticated guesswork–with it, they’re trustworthy virtual replicas.

Cloud Collaboration: Eliminating Geographic Barriers

The notion of location-bound project teams has become obsolete. Global expertise now flows freely across time zones, with specialists collaborating on unified models regardless of their physical location. Construction projects often run 20% over schedule and 80% over budget, with a leading cause being collaboration issues. Cloud collaboration address this; this borderless approach to construction expertise has opened new possibilities for problem-solving and innovation.

In the past, security concerns often held organizations back from embracing cloud solutions. Those barriers have largely crumbled. A 2021 Autodesk/FMI study found 79% of firms now trust cloud platforms to protect sensitive IP, a major shift from just a few years ago. Sophisticated protection mechanisms specifically designed for construction’s unique intellectual property challenges are now prevalent. These safeguards have given even the most security-conscious firms confidence in cloud adoption.

The traditional divide between office and field has dissolved into a seamless digital continuum. Cloud platforms ensure that everyone, from designers to site supervisors, accesses the same up-to-date information in real-time. This constant synchronization has virtually eliminated the communication gaps that once plagued construction projects. The result? Fewer RFIs, faster decisions, and smoother project delivery.

Data Analytics Driving Predictive Construction

Construction’s vast repository of historical data has transformed from an archive into a strategic asset. McKinsey estimates that better use of project data and analytics could boost productivity by 14–15% industry-wide. Advanced analytics platforms now mine this information to reveal patterns that help teams anticipate and prevent potential issues before they materialize on site.

In material management, data-driven approaches have proven highly effective. Analytical procurement systems help minimize waste, improving efficiency, cutting costs, and reducing environmental impact.

Perhaps most importantly, predictive analytics has revolutionized construction safety. Early adopters of safety incident prediction algorithms have reported up to 30% fewer reportable incidents demonstrating how data-driven insights can protect both workers, project timelines, and safety. Beyond statistics, these efforts ensure workers return home safely at the end of each day.

Reality Capture Technology Improvement & Adoption

Modern TLS & SLAM scanners continue to push the envelope of precision and speed. Pictured: Topcon CR-P1.

The integration of laser scanning into daily site monitoring has revolutionized project documentation. With centimeter-level accuracy, these systems create comprehensive visual records that serve as unimpeachable evidence of construction progress, effectively reducing disputes and strengthening accountability.

A new generation of mobile reality capture tools has democratized access to precise site documentation. The emergence of user-friendly devices like the NavVis VLX, Trimble X7, and iPad-based LiDAR scanners has transformed what was once a specialist’s domain into an accessible everyday tool. VDC teams, superintendents, and subcontractors can now capture detailed site data with minimal training, creating a seamless flow of real-world information into BIM systems. This accessibility has accelerated coordination, progress tracking, and prefabrication planning, making reality capture an integral part of daily construction operations. It’s no longer a question of if you’ll adopt these tools–it’s when.

Modular Construction and Digital Prefabrication

The construction industry has embraced vast libraries of pre-engineered components, fundamentally changing how designers approach their work. Instead of starting from scratch, they can now build virtually using real-world manufactured parts, significantly reducing the need for costly custom solutions.

Digital workflows have created a direct pipeline from design to fabrication. When implemented properly, this seamless connection minimizes errors while enabling precise just-in-time manufacturing schedules. What follows is a dramatic reduction in storage requirements on space-constrained construction sites. According to McKinsey, modular and prefabricated construction can cut project timelines by 20–50% and reduce costs by up to 20%, while also improving quality control.

To connect prefabrication with field reality, construction teams increasingly rely on ClearEdge3D’s Verity software. The system helps construction teams adapt prefabricated elements to actual site conditions, maintaining high quality standards while accommodating the inevitable variations found in real-world construction. As noted by Dodge Data & Analytics more than 60% of contractors report improved schedule performance when using model-based prefabrication. Without this validation layer, prefabrication is just a gamble–with it, it’s a reliable construction strategy.

Workforce Evolution and New Skill Requirements

The construction professional of today bears little resemblance to their counterpart from a decade ago. Estimators, project managers, and superintendents now routinely navigate complex digital tools, marking a fundamental shift in the industry’s skill requirements.

Success in 2026’s construction landscape, and beyond, demands a unique hybrid of expertise. The most valuable professionals are those who can seamlessly bridge the physical and digital realms, translating traditional construction knowledge into technological solutions. These “digital craftspeople” have become the cornerstone of modern construction teams. Their expertise encompasses understanding technology and applying it effectively on real job sites.

According to Christian Waldo, “The role of VDC (Virtual Design and Construction) professionals is gradually evolving beyond coordination and model management into that of data managers. As projects generate exponentially more information—from reality capture to BIM to IoT—VDC leaders are being tasked not only with visualizing and integrating models but also with structuring, governing, and extracting value from project data. Their expertise is increasingly focused on ensuring data quality, interoperability, and accessibility across the lifecycle, positioning them as critical stewards of the project’s digital backbone.”

Embracing the Next Generation of Construction Technology

Construction firms that recognize and adapt to these technological shifts are pulling ahead of their competitors. The advantages in efficiency, accuracy, and client satisfaction have become too significant to ignore. What we’re seeing is a widening and increasingly unbridgeable gap between technology leaders and laggards.

Ready to position your company at the forefront of these industry developments? Book a demo and discover how ClearEdge3D’s automated scan-to-BIM solutions can transform your construction workflow.

About the Contributor

Christian Waldo

Christian Waldo is a VDC manager at Hensel Phelps, having led the implementation and advancement of Building Information Modeling (BIM) technologies across a wide range of projects. With extensive experience deploying digital solutions in all major market segments and contract delivery methods, Christian has become a trusted voice in the Pacific Northwest AEC community.

Throughout his career, he has focused on making construction technology practical and impactful, streamlining workflows, improving cost efficiency, and reducing the environmental footprint of the built environment. His work emphasizes the role of technology as a bridge for collaboration, ensuring that owners, designers, and builders remain aligned from concept through delivery and beyond.