In the architecture, engineering, and construction (AEC) industry, project teams are constantly balancing two forces: speed and accuracy. Schedules grow tighter, sites become more complex, and budgets leave little room for error. Capturing and delivering reliable data has always been essential, but today it’s also a race against time.

The Cost of the Gap

That tension shows up in familiar ways. Teams wait days or weeks for scans before they can even begin modeling. Manual processes turn what should be straightforward deliverables into bottlenecks. On active job sites, errors aren’t caught until construction is already out of tolerance, forcing expensive rework and putting schedules at risk.

Owners and contractors are left asking for the impossible: results that are both fast and reliable. Most workflows force a tradeoff. The faster you move, the less you can trust the output. The more accurate you try to be, the longer the delays.

But what if speed and accuracy didn’t have to compete?

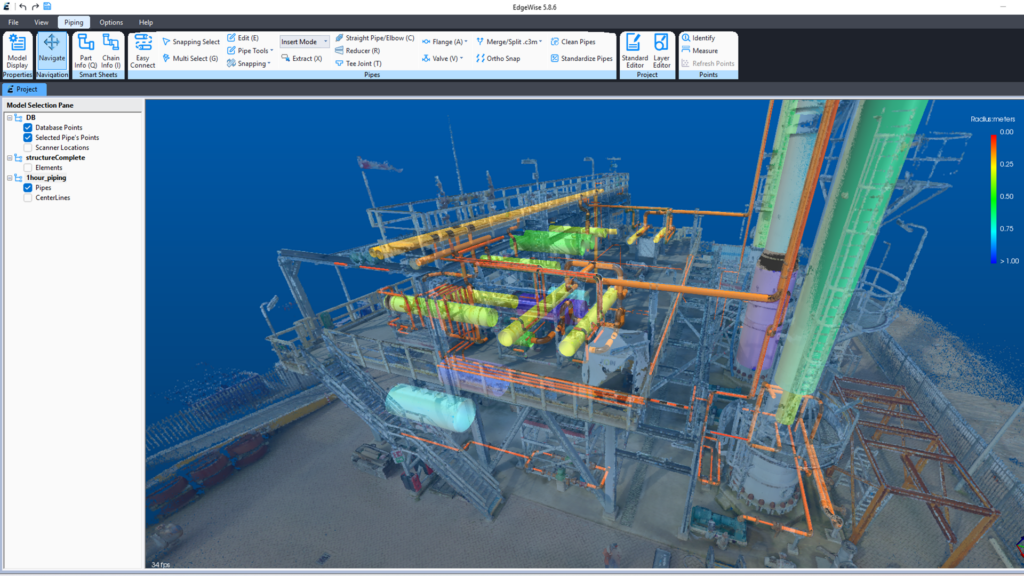

Extracting piping from NavVis VLX 3 laser scan data using ClearEdge3D EdgeWise.

The Partnership: ClearEdge3D + NavVis

That’s where NavVis and ClearEdge3D come together.

NavVis brings high-quality mobile mapping technology that can capture entire facilities in a fraction of the time once required. Its systems allow technicians to walk a site and produce dense, detailed point clouds in hours instead of weeks. Features like survey-grade control point integration ensure that even the largest, most complex datasets align cleanly and with confidence.

ClearEdge3D transforms that data into project-ready deliverables. With EdgeWise, point clouds become intelligent BIM models faster and with far less manual effort. With Verity, fresh scans are compared directly against design models to identify installation errors before they cascade into bigger issues.

The technologies don’t overlap; they complement each other. NavVis accelerates capture in the field. ClearEdge3D accelerates deliverables in the office. Together, they close the gap between raw data and reliable results.

Solving Pain Points Across Workflows

Scan-to-BIM: From Point Clouds to Models

On design and documentation projects, as-built models are often the critical path. But the old workflow—wait for TLS capture , then spend weeks manually tracing pipes and structures in Revit—creates delays and introduces opportunities for human error.

Extracting structural steel from NavVis VLX 3 laser scan data using ClearEdge3D EdgeWise.

With NavVis and ClearEdge3D, project teams start faster and finish faster. NavVis scanning delivers a complete dataset almost immediately, allowing modelers to begin work in parallel with capture. Once the data is available, EdgeWise automation extracts piping, structural steel, ductwork, and other major elements directly from the point cloud. Manual tracing is minimized, accuracy is preserved, and timelines shrink.

For firms tasked with documenting industrial facilities, plants, or multi-level buildings, that means predictable schedules and deliverables in a fraction of the time.

Construction Verification: Catching Errors Before They Cost You

On active construction projects, the pain looks different. Mistakes in the field compound quickly, and traditional QA methods—spot checks, visual inspections, tape measures—can only catch so much. By the time deviations are discovered, rework is expensive and deadlines are already in jeopardy.

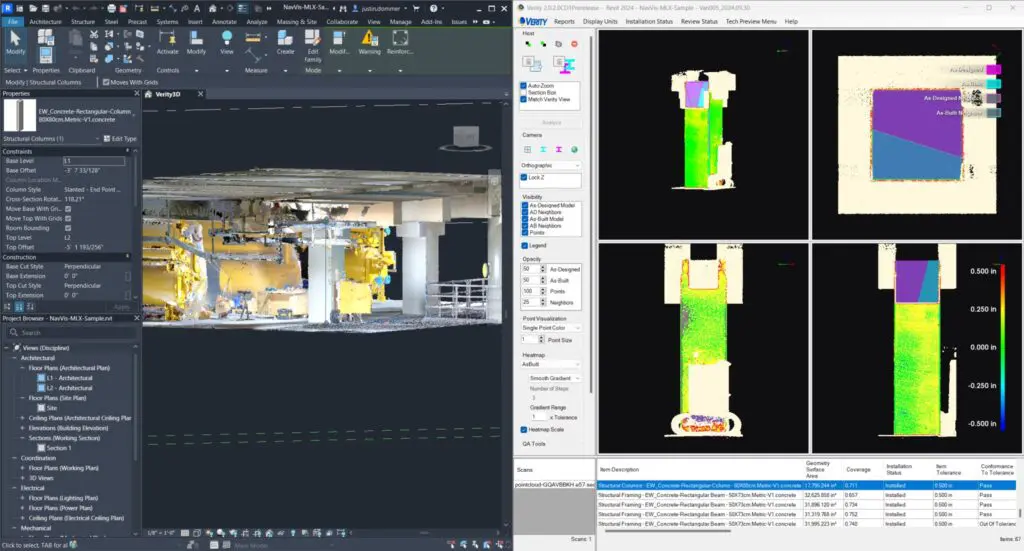

Performing construction verification analysis to validate the placement of a concrete column in ClearEdge3D Verity using laser scan data from a NavVis MLX.

Pairing NavVis capture with ClearEdge3D Verity changes the equation. NavVis systems provide high-quality scans of current conditions in a matter of hours. Verity then compares those scans against the design model inside Navisworks or Revit, automatically flagging what’s out of tolerance and what hasn’t been installed. Instead of reacting to problems after the fact, project managers can proactively identify them and generate field-ready reports to mitigate their impact.

The result is fewer surprises, less rework, and more confidence that construction is proceeding according to plan.

Case in Action: AECOM Wastewater Facility

AECOM’s Digital Practice Innovation group put this workflow to the test on a wastewater treatment facility with one of the most challenging environments imaginable: a sprawling, multi-level layout extending 150 feet underground, dense MEP systems, and a compressed delivery schedule. The goal was a Revit as-built model meeting LOA 200 accuracy requirements.

A point cloud of the sprawling wastewater treatment facility created by combining data from a NavVis VLX and Leica RTC360.

The team developed a hybrid approach:

- Rapid Capture with NavVis VLX

AECOM used the NavVis VLX to quickly capture each level of the facility. Control points throughout the site ensured alignment across datasets. Capture took only a single day, giving modelers immediate access to data.

- Early Modeling with EdgeWise

While TLS scanning continued for additional precision, the modeling team didn’t wait. They loaded NavVis data into Revit and processed it in EdgeWise, which automatically generated much of the piping and conduit model. This early start gave the team a head start on deliverables before the full dataset was even complete.

- TLS Integration for Precision

When TLS data arrived two weeks later, it was processed in EdgeWise to refine and complete the model. Automated feature extraction accelerated the process, while manual adjustments ensured the highest accuracy.

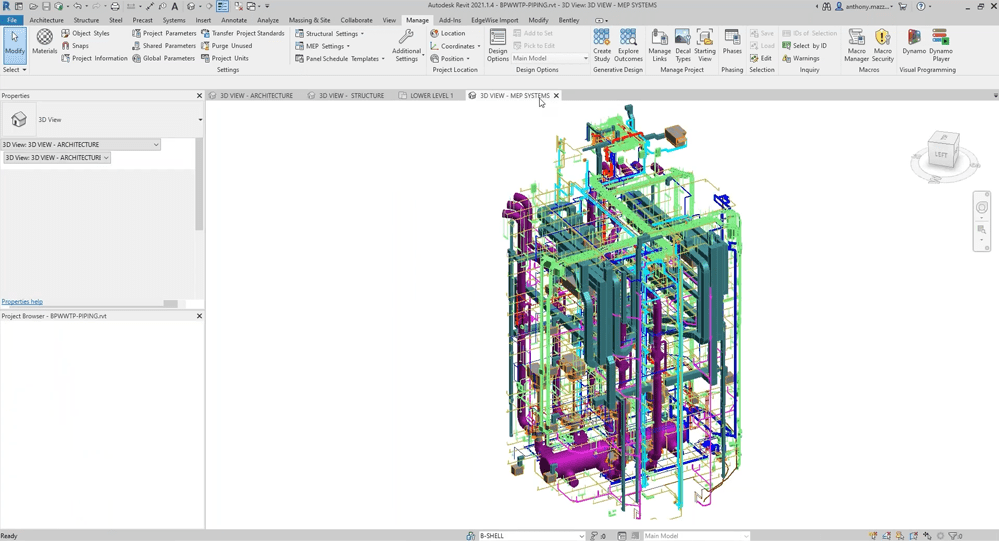

A Revit model of the facility’s HVAC and MEP system created using ClearEdge3D EdgeWise.

The results were undeniable: a project that might have taken seven weeks was delivered in just four. Roughly 40% of the piping and conduit was modeled automatically, with accuracy measured within 0.08 inches. Most importantly, speed didn’t come at the expense of quality. The final model aligned seamlessly across NavVis and TLS datasets, creating a dense, reliable point cloud and a precise as-built model.

AECOM’s summary said it all: “It’s the important kind of speed, the speed of actually being able to do your work. This workflow was a huge time saver.”

Beyond a Single Project

AECOM’s success highlights how powerful the combination of NavVis and ClearEdge3D can be, but the workflow isn’t limited to wastewater facilities.

- For as-built modeling, the same approach applies to industrial plants, commercial construction projects, data centers, and manufacturing sites—environments where accurate piping and structural models are essential.

- For construction verification, pairing NavVis with Verity provides value across a wide range of building projects, where catching out-of-tolerance work early can mean the difference between staying on schedule or falling behind.

For project teams, the benefits are clear: faster deliverables, higher confidence in results, reduced rework, and documentation that stands up to scrutiny.

Conclusion

Every project team wrestles with the same challenge: how to move fast without cutting corners. The partnership between NavVis and ClearEdge3D proves that speed and accuracy don’t have to be at odds. NavVis accelerates capture. ClearEdge3D accelerates deliverables. Together, they give teams a faster, more reliable path from field data to confident decisions.

For firms competing on both time and quality, it’s not just a better workflow, it’s a smarter way to deliver.