Scan to BIM Success on the First Try

Scan to BIM Success on the First Try

How Nijhuis Saur Industries completed its first ever industrial scan-to-BIM project 66% faster with Edgewise, saving $20,000 of tedious modeling work.mpleted its first ever industrial scan-to-BIM project 66% faster with Edgewise, saving $20,000 of tedious modeling work.

Ted

Heads the UK Digital Design group of Nijhuis Saur

Here’s How:

About The Project

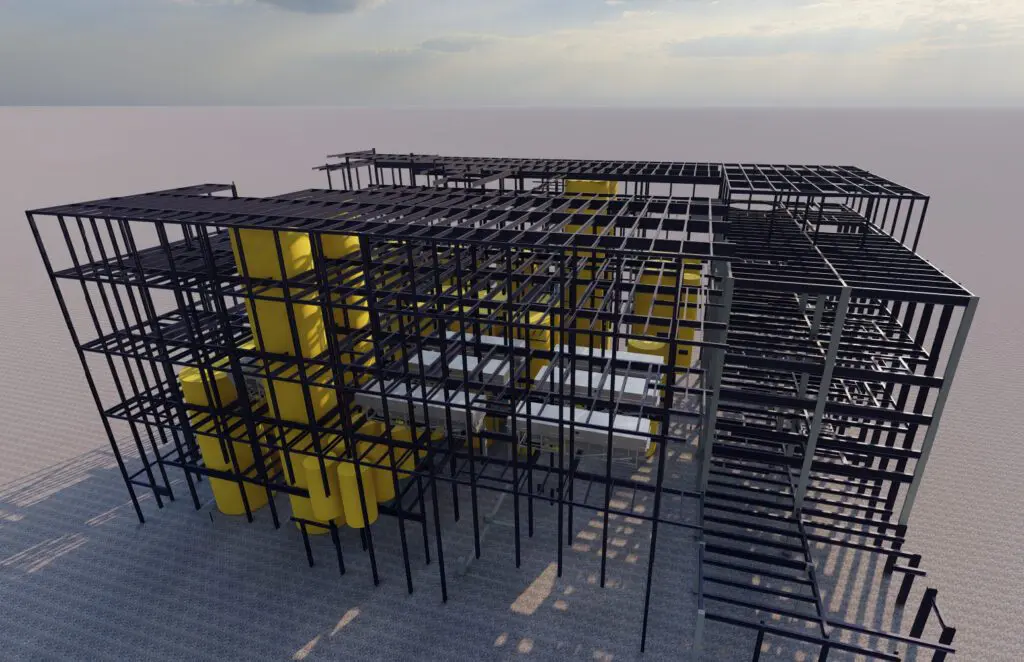

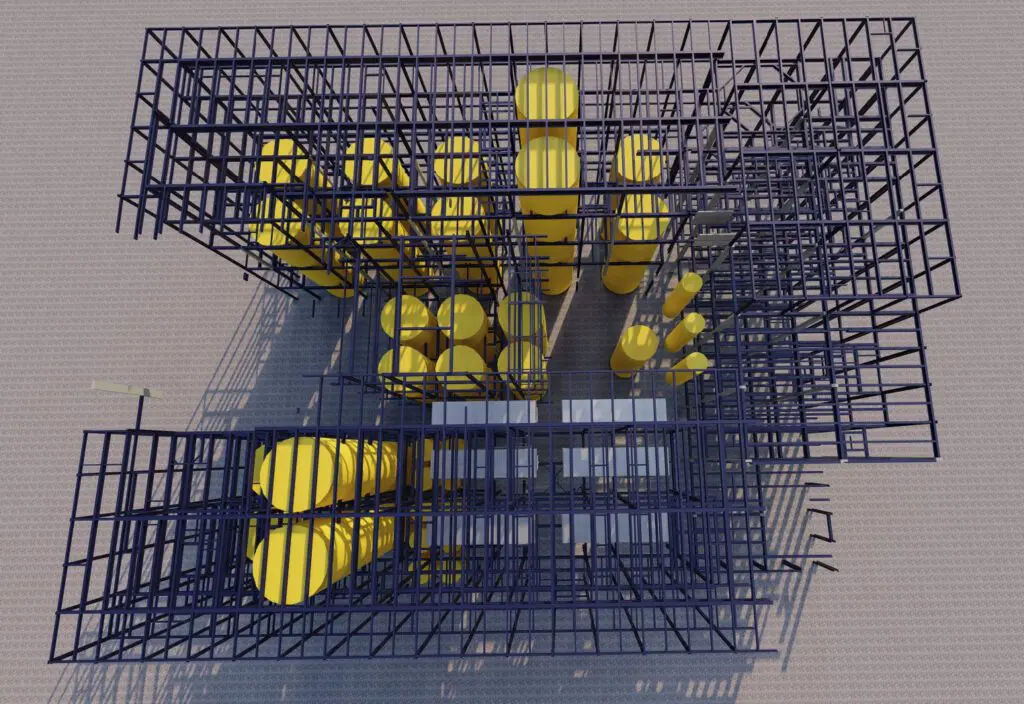

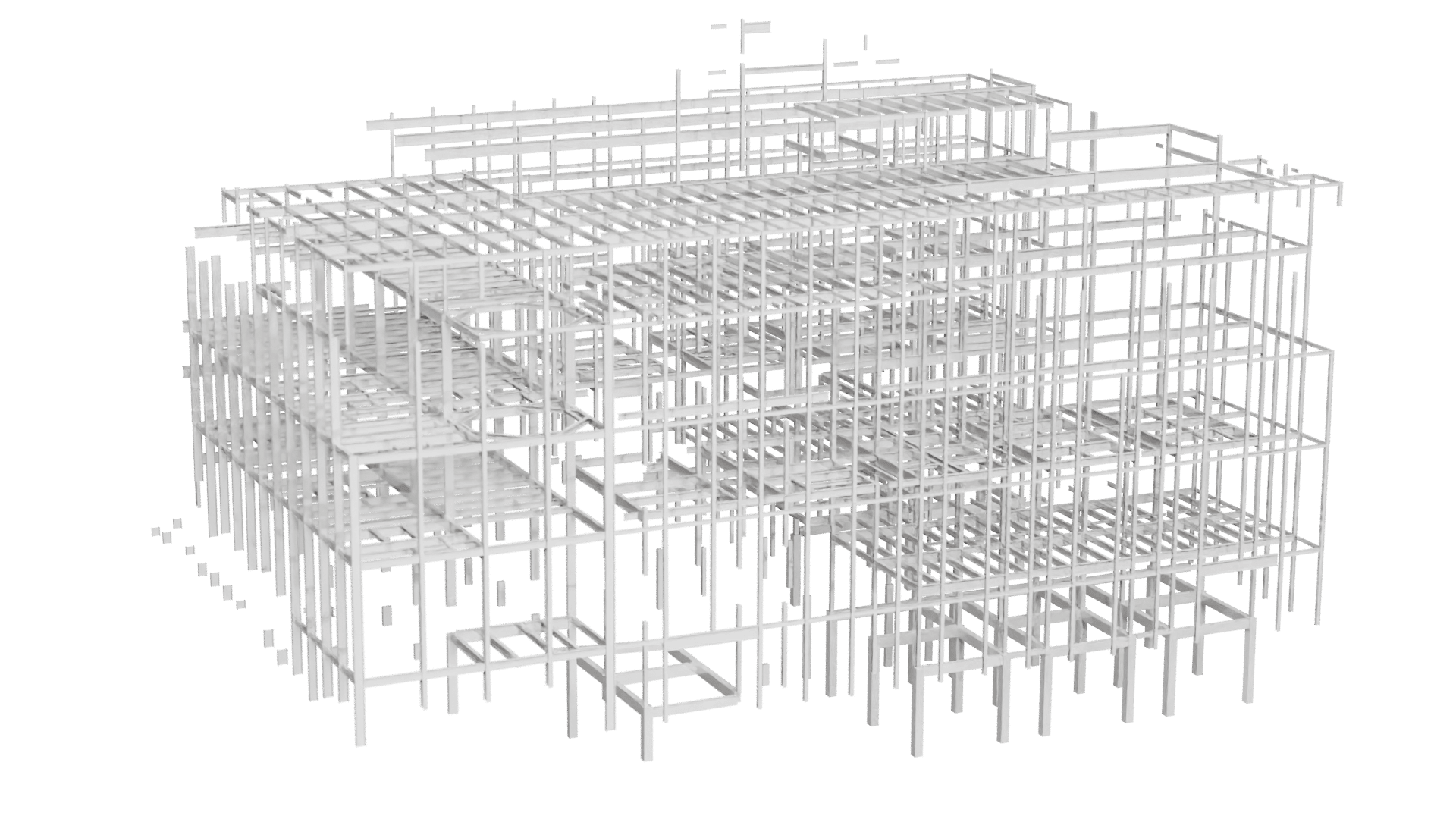

Goal: Scan, model, and re-design a disused seven-story wastewater treatment plant in continental Europe

Ted’s Mission: Deliver a 3D point cloud and Revit model of the facility to enable concept design for repurposing the plant.

This highly complicated industrial site would prove difficult for even the most seasoned BIM professionals. That coupled with a stringent project timeline would leave many in Ted’s position shaking in their boots.

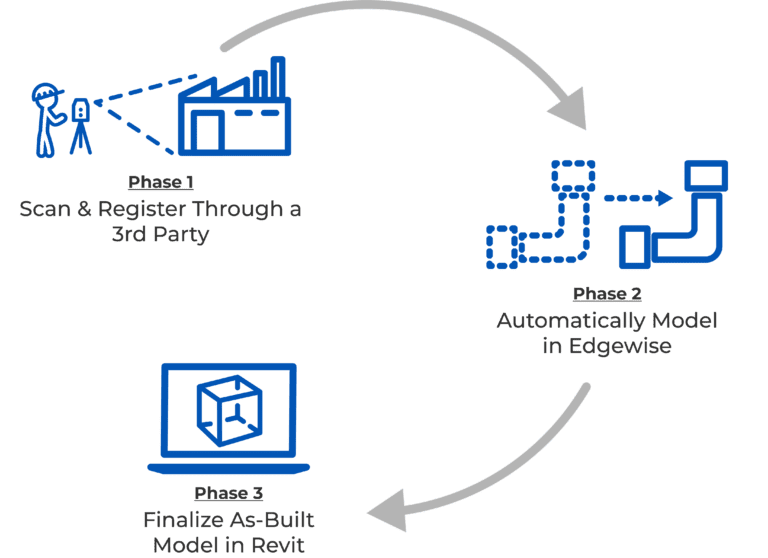

The Winning Workflow

Phase 1: Data Capture & Registration

Third party scanning and data processing from a team in the local country

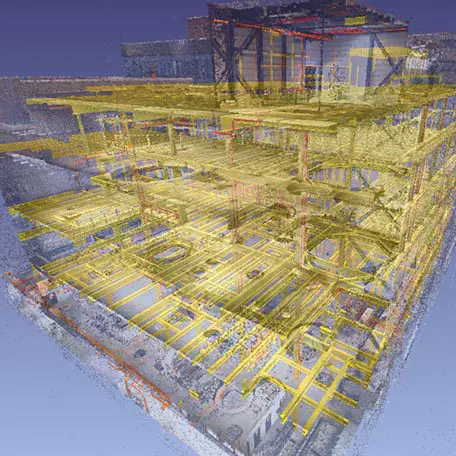

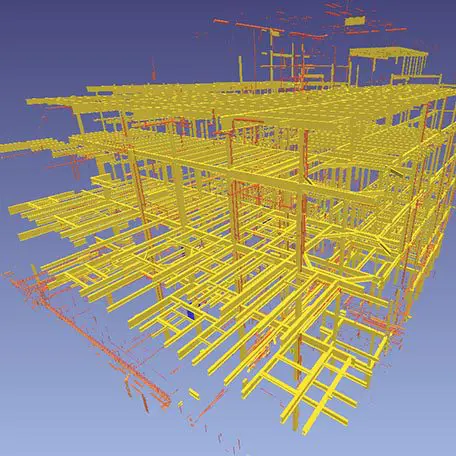

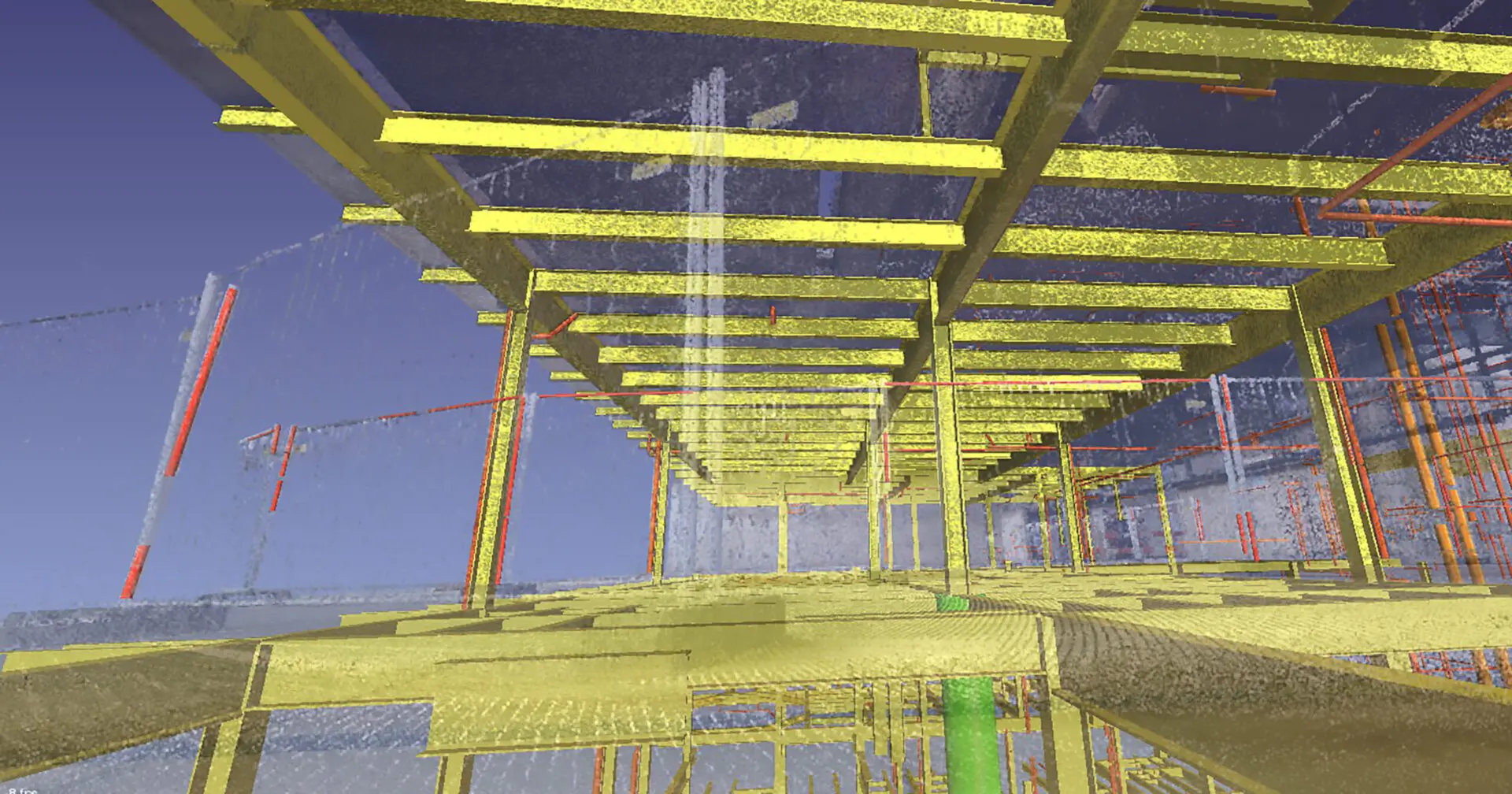

The third-party team scanned the site over five days using FARO S150 scanners. The 180 GB point cloud was then registered and transferred to the Nijhuis team.

Phase 2: Automated As-Built Modeling Using EdgeWise

Ted modeled all the steel and MEP from the registered data set using EdgeWise’s automated and semi-automated tools in just three weeks.

Phase 3:Clean Up In Revit & Project Delivery

Ted completed a lion’s share of the modeling in EdgeWise before passing the file to his colleague to finish in Revit.

By leveraging EdgeWise’s automated modeling capabilities, the team successfully delivered this impressive model in just 3 weeks!