Automate error detection across full entire scopes of work. Identify issues up to 85% faster than traditional methods, reducing reliance on incomplete spot-checks and improving QA.

Verity: Construction Quality Control Software

Identify Construction & Modeling Errors 85% Faster with Automated QA/QC

What is Verity?

ClearEdge3D Verity is an automated construction verification and model QA/QC tool that helps teams avoid costly installation and modeling errors. By rapidly comparing as-built point clouds with models in Autodesk Revit and Navisworks, Verity identifies mistakes up to 85% faster than traditional methods. This ensures accuracy and prevents mistakes from escalating into expensive problems downstream.

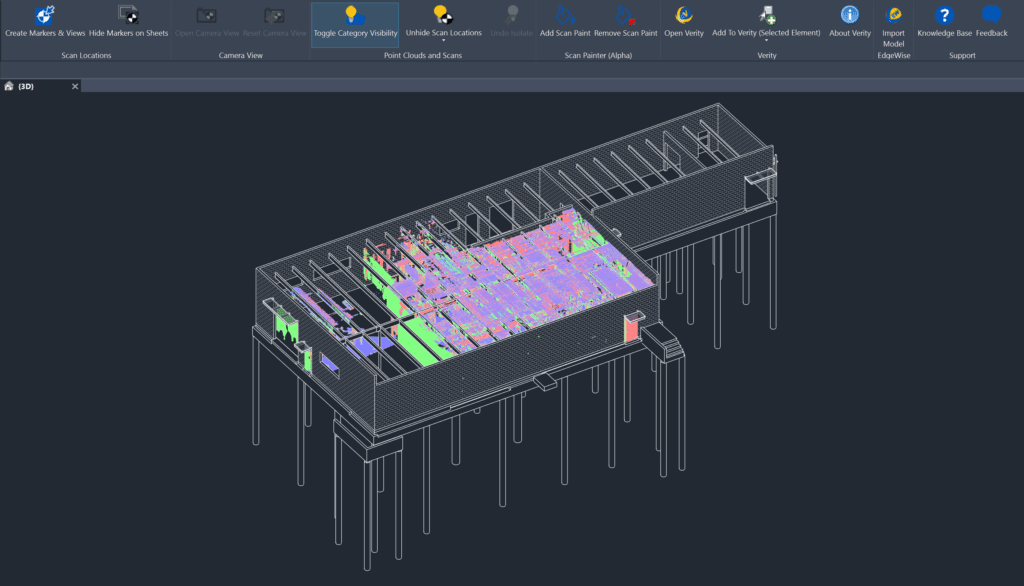

Automated QA/QC at Scale

Automate comparing as-built point clouds with design and coordination models, identifying errors up to 85% faster than traditional methods. Verity streamlines QA/QC workflows for building construction and as-built modeling, ensuring accuracy and preventing costly mistakes. It efficiently handles large data sets, eliminating blind spots from spot checks and other manual QA methods to reduce project risks.

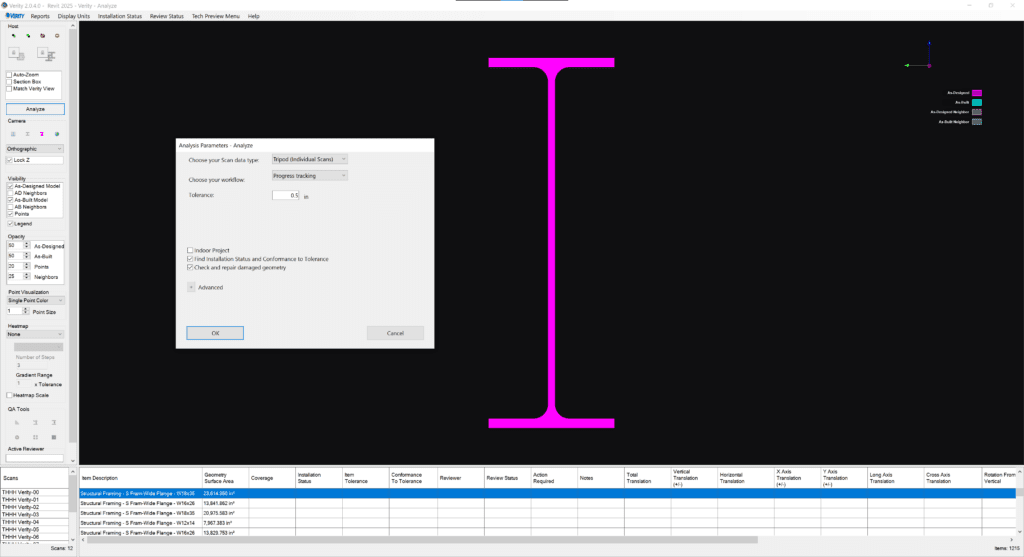

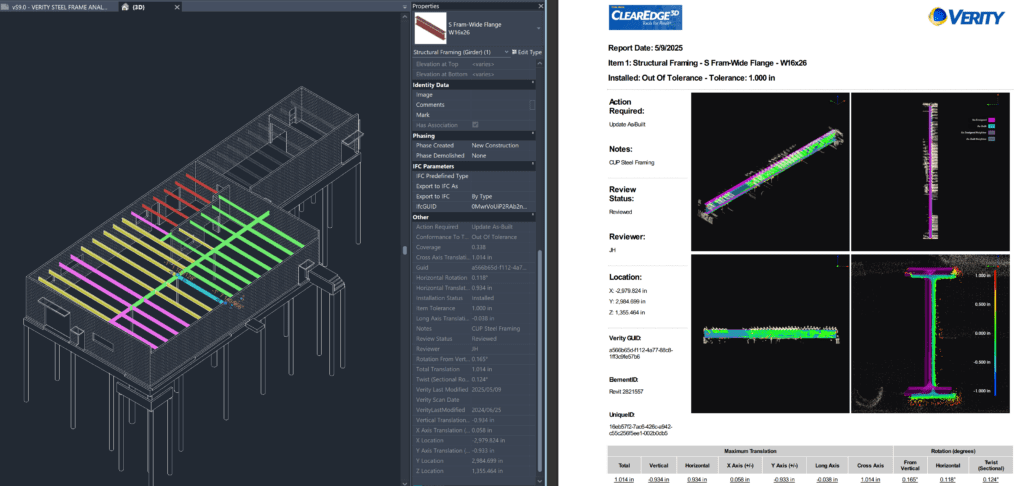

Visual Error Detection and Reporting

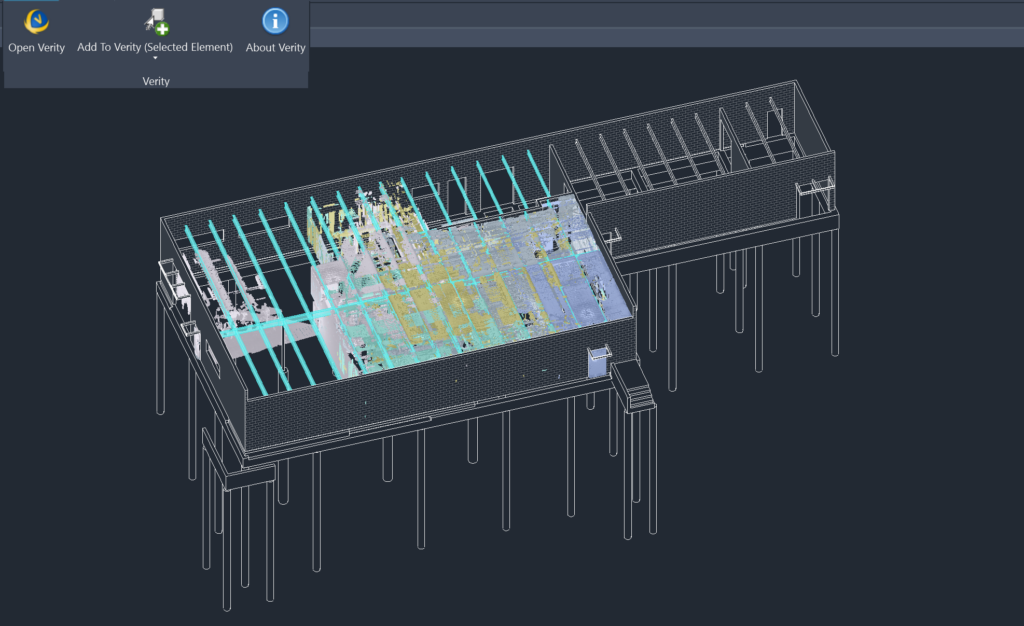

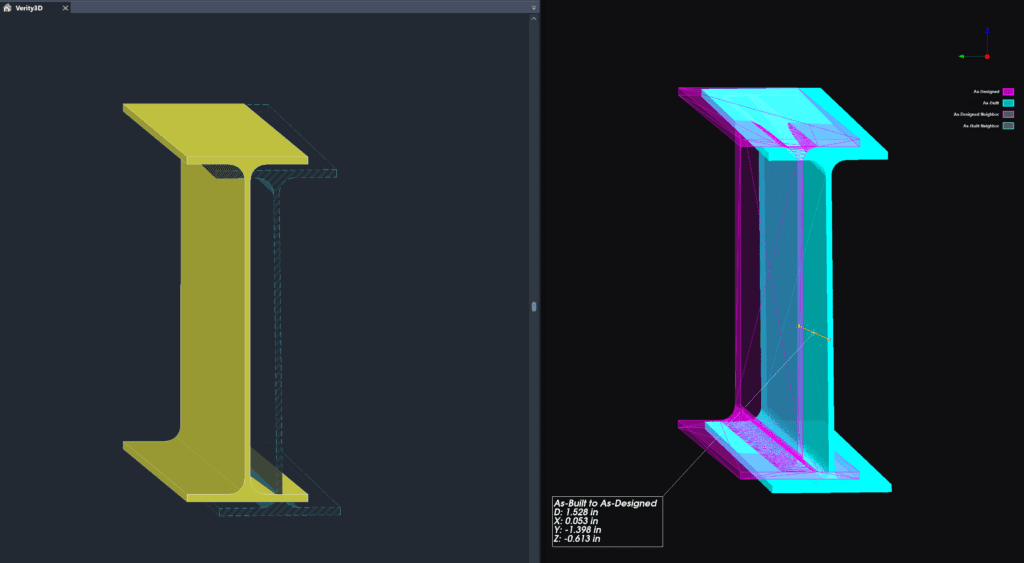

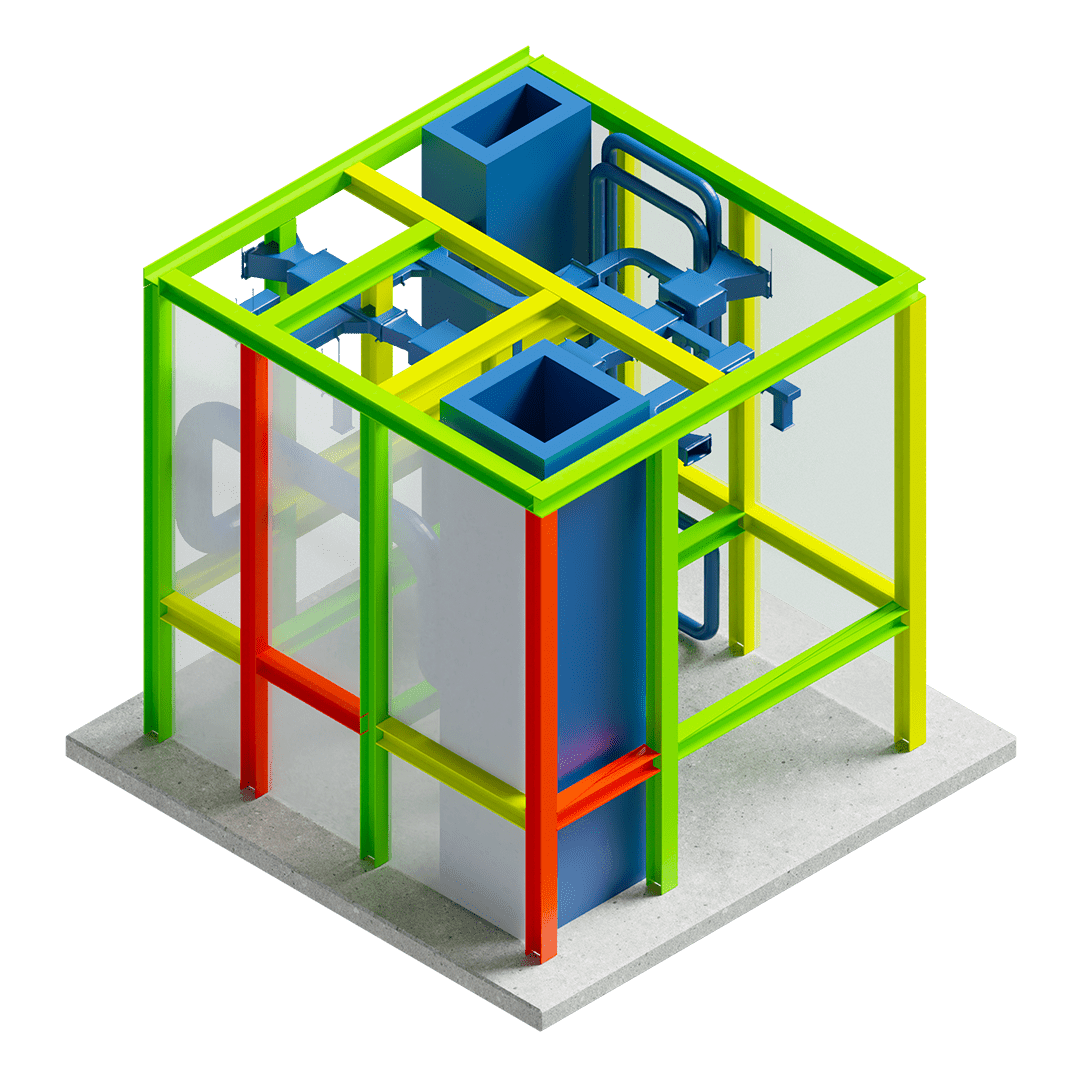

Color-coded models highlight in-tolerance, out-of-tolerance, and not installed elements, making issues easy to spot for anyone—not just software specialists. Verity seamlessly shares data with Revit and Navisworks, allowing teams to create sheets, schedules, and reports using their built-in tools—or generate native HTML and PDF reports to keep stakeholders informed and ensure clear communication.

Enhanced Model Accuracy & Coordination with As-Built Data

Update Autodesk Navisworks® or Revit® models to reflect as-built conditions with just a few clicks. Automatically generate true as-built geometry for elements that deviate from the model. Use clash detection and coordination workflows to assess deviation and keep projects on track.

Direct Integration with Revit and Navisworks

Easily compare as-built point clouds with models in Autodesk Revit and Navisworks. Verity transfers data effortlessly between both platforms, ensuring accurate model updates while enriching models with metadata from the analysis. This direct integration simplifies adoption and improves project accuracy.

The Verity Advantage

Catch errors early to prevent costly rework and keep projects on schedule. Verity helps teams reduce rework costs, minimize disruptions, and maintain control over timelines for greater efficiency.

Color-coded models and detailed reports provide clear visual insights into installation errors for all stakeholders. Generate intuitive HTML and PDF reports or 2D sheets and schedules in Revit to document and communicate issues, keeping teams aligned without requiring specialized BIM expertise.

Quickly update Revit and Navisworks models to reflect true field conditions, improving project quality. Better alignment reduces clashes and errors while ensuring teams deliver accurate, reliable models that match real-world construction.

5 Steps to Smarter, More Reliable Construction QA/QC

A Faster, More Accurate Approach to Verifying Installations

Here's What Our Customers are Saying

Frequently Asked Questions