Search Knowledge Base by Keyword

Getting Started

This article will cover general information regarding the Unstructured Process Scans workflow. Process Scans is the first step in any EdgeWise Project, and consists of three different workflows: Structured, Unstructured, and Point Database Process Scans.

The unstructured workflow supports automatically extracting pipes and walls. The scan files need to be registered, and unstructured/unified before using the Unstructured Process Scans workflow.

File Types

The specific unstructured file types that can be brought into EdgeWise are as follows:

- .E57 (Un-Structured)

- .PTS

- .RCP

- .RCS

- .XYZ

Process Scans

To process unstructured scans, first click the Process Scans button located under the file tab, to the top left of the screen.

Upon clicking the Process Scans button, the Process Scans dialogue box will appear. To proceed with Unstructured Data, click the Use Unstructured Workflow button at the bottom of the dialogue box.

Fig 2: Unstructured Process Scans

After you click the Use Unstructured Workflow button, a File Explorer will appear. Navigate to the location of your scan file(s), select all of your scan file(s), and click the Open button.

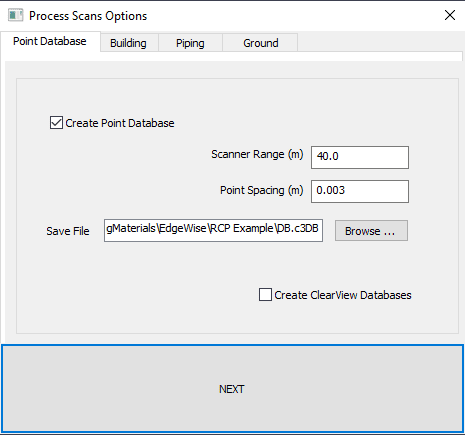

After clicking the Open button within the File Explorer, the Process Scans Options dialogue box will appear.

The Process Scans Options dialogue box allows you to choose which modules will be automatically processed in addition to changing the respective modules’ processing settings. The various sections below, cover each module’s settings in detail.

Point Database

Before EdgeWise can display a point cloud, you must first convert your scans to a .c3db point database model.

- Scanner Range – EdgeWise uses this parameter to determine how far away from the scanner location points are can be to be included in the database, because unstructured scan files do not contain scanner locations, and therefor points cannot be assigned an accurate distance from the scanner. The Max Range parameter is locked to 10,000 meters when using unstructured file types, to ensure that all data is included.

- Point spacing -the minimum spacing between points saved in the database. The larger the number, the sparser the point cloud will be. Denser point clouds may look slightly better, but they take considerably more disk space and time to create.

- Create ClearView Database – is an option to create a point database used for viewing the project using the ClearView setting—see ClearView Mode. However, EdgeWise cannot create ClearView databases from unstructured scan files, as they do not contain scanner locations.

Building

EdgeWise will automatically extract walls and levels in this automated process. In addition, support is available for this process for the Structured, Unstructured and Database workflows, and supports all available file types. Check Automatically Extract Wall Model and EdgeWise will automatically create a wall model during process scans. If you do not wish to extract walls, simply un-check the box.

Wall Extraction Distance Tolerance – When EdgeWise is attempting to automatically detect a wall, this tolerance controls the maximum distance a point can be from the surface of the wall while still being used for the extraction process. The algorithm will not use Points outside of this distance from the surface of a wall in the extraction process for that wall.

Minimum Distance Between Levels – During Automatic Level detection, this parameter will limit the creation of levels within the specified distance of an already detected level, essentially reducing the number of duplicate or superfluous levels.

Piping

Automatically extracts pipe models with the Automatically Extract Pipe Model box selected.

- Extraction Mode – chooses which piping automation algorithm EdgeWise uses during extraction.

- Minimize False Positives attempts to filter out more non-cylindrical items and other false positives.

- Maximize Number of Extractions will result in the most number of good cylinder extractions, but possibly have more false positive extractions.

If your scanner has a low noise level and there was good scan coverage of your project, you should choose Minimize False Positives. If your scanner has a high noise level or you have poor scan coverage of your project, you should instead choose Maximize Number of Extractions.

Remove Pipes outside of Diameter Range – preemptively define a range of diameters to be extracted with Edgewise, use this to automatically remove unnecessary cylinders from your model.